How to build a continuous improvement culture that lasts

Georgina Guthrie

July 02, 2025

If your team’s stuck firefighting or frustrated by slow progress, a continuous improvement culture might be the shift you need. But can you really improve something forever? Surely there’s a limit, right?

Well, yes and no. The real limit to this isn’t what you’d imagine — that the project or process has reached perfection. Perfection isn’t the goal. It’s momentum. And that’s no easy task.

In this guide, we’ll explore how to create a continuous improvement culture that actually sticks — including the five principles that power it, step-by-step implementation strategies, and the tools that make it easier to stay on track.

Why most continuous improvement efforts fail

Everyone says they want to improve. Most teams don’t know how.

That’s the truth about continuous improvement (CI). It sounds like a good idea in theory — who wouldn’t want less waste and happier customers? But in practice, many CI efforts stall out within months. Not because teams don’t care, but because the culture, systems, and leadership signals around them aren’t designed to support sustainable change.

Too often, CI gets treated as a side project, or worse, a one-off initiative. Leadership sends a few people to Lean training. A retrospective turns into a to-do list. Someone launches a “process improvement board” — and two months later, it’s collecting dust.

The problem isn’t the concept. It’s the follow-through, and more importantly, the environment in which teams are asked to do it.

For continuous improvement to take root, it needs to be more than a process. It has to be a mindset and a system that supports action, not just good intentions. And you need to build it into your organization’s culture.

What a real continuous improvement culture looks like

A continuous improvement culture isn’t a quarterly strategy review or a poster on the wall. And it’s definitely not a checklist someone revisits once a year.

A true continuous improvement culture is alive and embedded in the life of your organization. It shows up when people feel safe to challenge how things are done — and confident they’ll be heard. It’s when a junior developer fixes a bottleneck, or a frontline manager runs a quick test to speed up onboarding, without needing sign-off from three layers of leadership.

Here’s what it is:

- Teams regularly reflect and adjust how they work, without waiting to be told

- Small experiments, tested and shared across teams

- A continual quest to do things better, from adding value to reducing waste.

Here’s what it’s not:

- A once-a-year workshop on “what could we do better?”

- A dusty Kanban board from a CI initiative no one’s touched in months

- A top-down mandate that says “innovate more!” without giving time or tools to do it.

The benefits of a continuous improvement culture

The aim of the game? Delivering more value for customers and less waste for your organization. Kaizen (that’s continuous improvement in Lean speak) in a nutshell!

- Less waste, more progress: Teams work smarter by streamlining tasks and cutting pointless steps.

- Quality gets a boost: Regular tweaks help both products and processes run smoother.

- Customers notice: When things improve behind the scenes, your customers feel it too.

- People care more: When teams feel heard and their ideas get traction, motivation naturally follows.

- Problems get fixed faster: No more waiting for someone else to spot the issue — teams take ownership.

- Change doesn’t rattle you: The mood shifts from “this is how we’ve always done it” to “how can we do it better?”

- Learning becomes the norm: Getting things wrong isn’t a disaster — it’s just the first step to getting it right.

The 5 principles of a continuous improvement culture

These five principles (which do vary slightly, depending on who you ask) help teams stay focused and embed continuous improvement into daily work.

1. Focus on the customer

Every great improvement starts with understanding who you’re improving for. In a continuous improvement culture, the customer is the compass. Their needs, expectations, and experiences guide decisions at every level.

It’s not just about swatting away complaints — it’s about constantly asking “does this make life better for the customer?” Something that should be woven into every decision, from small changes to big new product ideas.

2. Empower employees

Change doesn’t just come from the top. When you trust people at every level to share ideas and make improvements, that’s when things really fly.

Empowerment means giving teams the tools and psychological safety to speak up. You don’t have to go full bottom-up management, but you do need to shift things from command-and-control to trust-and-support.

Example: Manufacturing shift lead reworks a clunky checklist

A frontline shift lead at a food packaging company noticed their quality check process was duplicated across two systems. No one had questioned it before, but it was costing each worker 20 minutes per shift. After surfacing the issue during a daily standup, she proposed a simplified checklist that worked for both systems. With management’s support, they piloted it and saved over 100 hours in the first month alone. Her team now holds regular “efficiency huddles” to surface similar ideas.

3. Be data-focused and transparent

Teams should use data to test solutions and learn from outcomes, whether things go right or wrong. One to know is the PDCA cycle (which stands for Plan-Do-Check-Act). It’s an offshoot of Lean and helps you take a methodical, data-oriented approach to improvements.

Just as important is openness: sharing what’s working (and what’s not) so others can learn, too. It’s a mindset of discovery over blame, and learning over perfection.

4. Create flow efficiency

Efficiency isn’t about squeezing people or cutting corners. It’s about creating smoother and more reliable ways to deliver value.

That means spotting where work gets stuck — bottlenecks, superfluous steps — and redesigning processes so things flow. The goal is to create a steady, frictionless path from idea to outcome.

For example, a software team might spot that approvals from legal delay product releases. By adjusting when legal reviews occur, they cut the bottleneck and speed up delivery.

5. Actively seek perfection

Perfection might sound intimidating, but in a continuous improvement culture, it’s not about being flawless. It’s about always reaching for better. Over time, these micro-improvements compound into major gains.

Understanding waste: The 3Ms

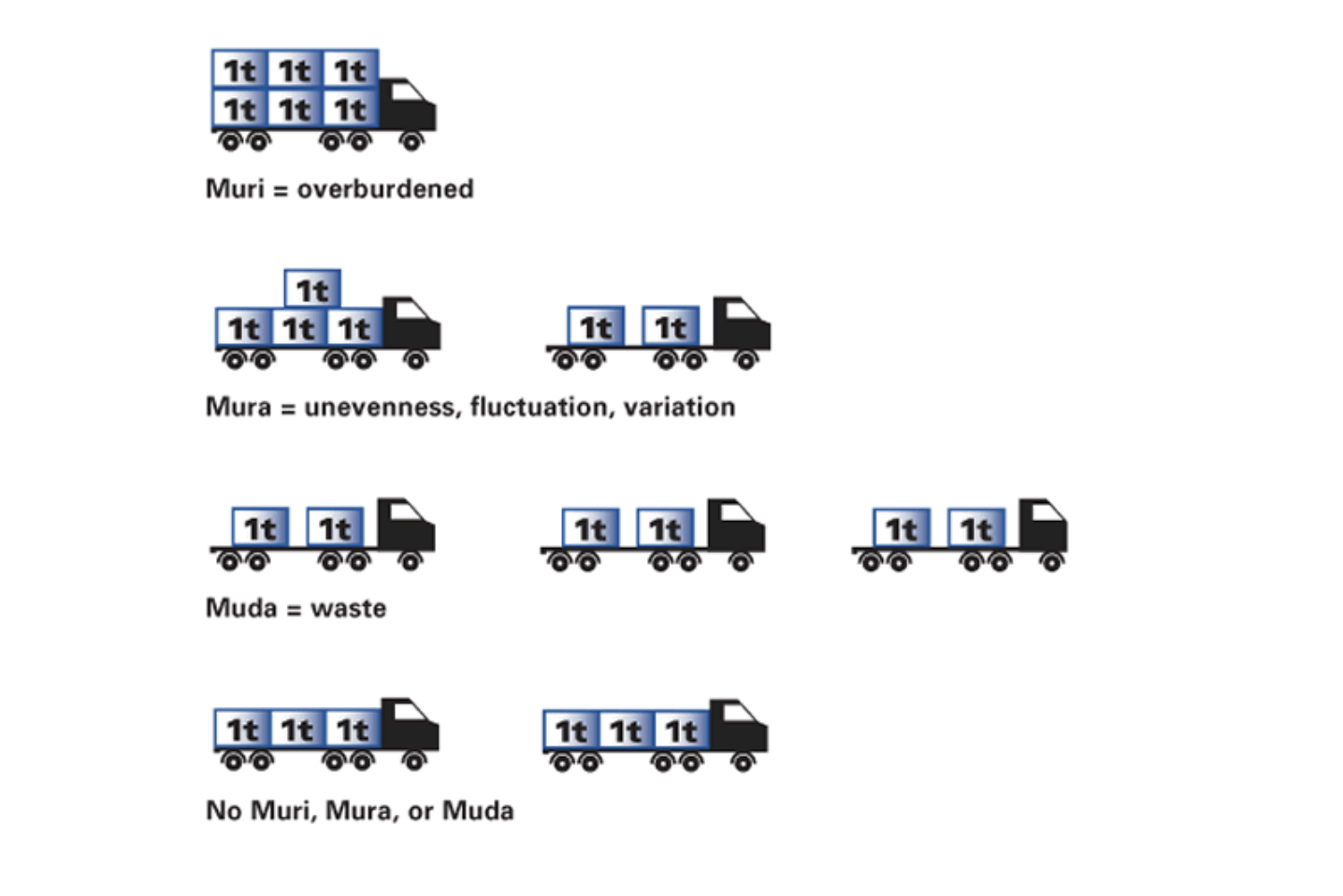

Waste shows up in sneaky ways — a task that sits idle, a report no one reads, a process done twice. But what counts as waste? According to Lean management principles, there are three types of waste, known colloquially as the three ‘Ms’:

- Muda: any activity that consumes resources without adding value to the customer. Lean Management identifies seven different types of waste in this context: transport, inventory, motion, waiting, overproduction, over-processing, and defects.

- Mura: waste through unevenness or inconsistency that causes customers or clients to hurry or wait. It stops your tasks from flowing smoothly and can create many of the seven wastes detailed above.

- Muri: waste caused by overburdening workers or suppliers, forcing them to work beyond their capacity and creating unnecessary stress. It’s usually caused by Mura.

How to implement a continuous improvement culture, step by step

You’ve got the mindset, the principles, and the motivation — now what? Here’s how to bring continuous improvement to life, phase by phase. At each level, the right roles need to step up in the right way.

1. Start with your systems and culture

Big change starts with looking at how your organization functions. You’ll need to align your systems, structures, and leadership behaviors so they support (not block) continuous improvement.

That might mean shifting from top-down control to more democrating decision-making, or creating new ways for teams to float ideas and feedback.

Who’s involved:

- Senior leaders model the mindset, champion the value of CI, and align systems to support it.

- Transformation or change teams help audit current structures and guide the cultural shift.

- HR and L&D play a role in embedding improvement into hiring, onboarding, and training.

2. Tie improvements to business strategy

Improvement efforts lose steam if they’re not tied to something bigger. Otherwise it risks becoming busywork. Leaders need to clearly define what “better” looks like, including setting measurable priorities, and allocating resources to help teams improve in the right direction.

This isn’t about micromanaging every change — it’s about framing the big picture and making space for experimentation.

Who’s involved:

- Executives and strategy leads define improvement goals that align with business outcomes.

- Middle managers help translate these goals into operational language for teams.

- Finance and planning teams allocate time and resources to support long-term value.

3. Improve key processes across teams

This is where the rubber hits the road. Once you’ve set the direction, focus on how work actually flows through your organization. Most bottlenecks and frustrations happen across departments, not within them, which is why you really need to fine-tune company-wide collaboration. Get teams to map out how they deliver value from idea to customer, then look for ways to cut waste and improve speed and quality.

Example: Cross-team delivery fix at a SaaS company

A mid-sized SaaS company kept missing release dates. Product blamed engineering, engineering blamed legal, and no one could see the full picture. A continuous improvement workshop mapped the full value stream — revealing a key bottleneck: unclear ownership of test environment access. Once they clarified roles rolled out a project management tool for better transparency, lead time dropped.

Who’s involved:

- Operational leads and process owners drive mapping and redesign efforts.

- Department teams bring different perspectives and reduce siloed decision-making.

- Middle managers remove roadblocks and escalate systemic issues as needed.

4. Build daily improvement habits

This is the heart of a true CI culture: small, team-led changes that happen every day. Remember, the aim is progress here, not perfection. Encourage teams to experiment and reflect (and give them the space and support to do that).

Who’s involved:

- Team leaders and supervisors create psychological safety, coach people on using CI tools, and celebrate wins.

- Frontline employees identify pain points and test solutions.

- Managers and leadership should stay visible, reinforcing that even small improvements matter.

Six continuous improvement techniques worth knowing

Once your team starts building daily habits of improvement, it helps to have the right tools at hand. These Lean techniques support problem-solving and keep your momentum going.

You don’t need to master them all at once, but knowing when and how to use them can make a big difference.

- Plan-Do-Check-Act (PDCA): A classic cycle for testing and refining ideas. Teams plan a change, try it out, check the results, and adjust based on what they learn. It’s great for nurturing a learning mindset supported by data.

- Five Whys: A simple technique that’s super effective. Keep asking “why?” — usually five times, but you might get there sooner — to move past surface issues and uncover the root cause. Often used within Root Cause Analysis (see below).

- Root Cause Analysis: When problems keep popping up, this helps you dig deeper. Rather than treating symptoms, you investigate what’s actually causing the issue — so it doesn’t come back again.

- Fault tree analysis: This visual approach maps out all possible causes of a failure or breakdown. It’s especially handy in high-risk or complex environments where multiple factors interact.

- A3 problem-solving technique: A structured method for tackling problems collaboratively. It walks teams through seven steps — from defining the issue to taking action — often using a single-page (A3-sized) report to track thinking and outcomes.

- Kanban: A visual way to manage work and improve flow. By tracking tasks on a board and limiting work-in-progress, teams can spot bottlenecks, avoid overload, and reduce inconsistency (aka Mura).

Bring it all together with the right tools

Even the most motivated teams need help making progress stick. And that doesn’t happen without commitment to workplace culture.

Project management tools like Backlog help bring this all together. With shared workflows, task visibility, and built-in collaboration, it gives teams a clear view of what’s working and where they can improve. Whether you’re fixing a small process glitch or rethinking how work flows across the org, visibility and alignment are what keep momentum going.

Ready to turn ideas into action? Try Backlog and start building your continuous improvement culture today.

This post was originally published on April 10, 2020, and updated most recently on July 1, 2025.